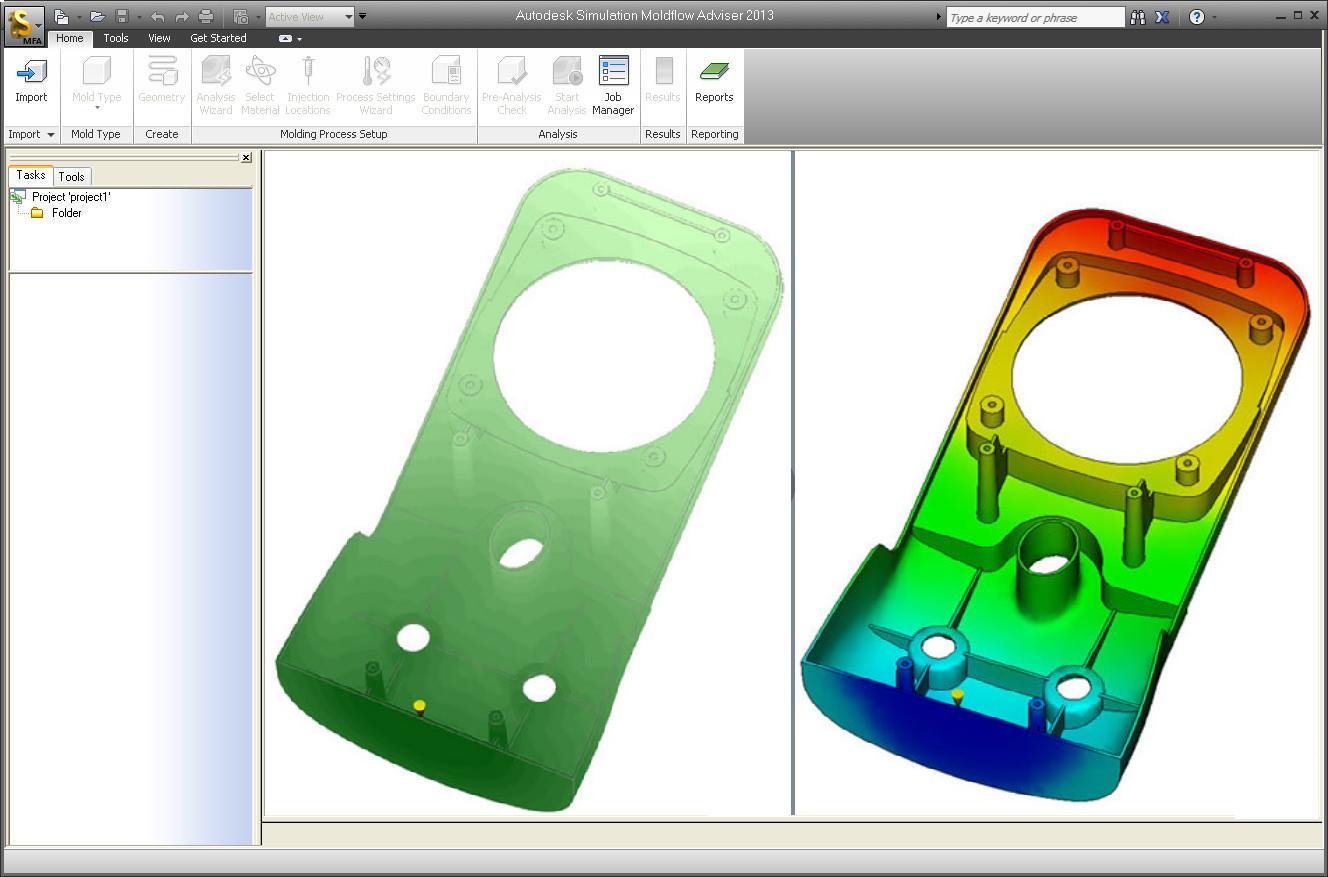

Melt rheology is the prime mover of flow behavior. Thermal properties (specific heat thermal conductivity and transition temperature).The following material properties are used by simulation to determine a material’s flow and pack behavior. With packing analysis, we are able to predict how packing pressure is distributed to different areas of the part, and how those areas shrink relative to one another. The filling pattern allows us to see if there is reasonable flow balance, determine whether the pressure and clamp-force requirements are reasonable, and whether or not the weld-line locations are problematic. The main objective of filling analysis is to predict the filling pattern based on the gating scheme and process conditions that were input to the model. The most often used simulations are for the filling and packing stages. So, rather than being a trash-loving Oscar the Grouch, let’s see what good material properties look like for a robust simulation. Otherwise, you could be in for a big surprise when you start molding parts. Would any of you like to build or run a mold based on a guess at the results? If you are responsible for reviewing Moldflow results, it is critical that you know how good the material data is. It’s the classic “garbage in, garbage out” (GIGO) scenario. The pictures generated from those results will look very nice, but they will likely be wrong. Any uncertainty in the quality of the data generated during material characterization will lead to uncertain results. It discusses material data required for Autodesk Simulation Moldflow Insight (ASMI), the most commonly used simulation software.ĭepending on what type of simulation is being done, there could be up to 10 sets of material properties needed to fully characterize a plastic material for analysis purposes. Additionally, particular attention must be paid to the material properties, which is the focus of this article. For injection molding simulation, the part and mold geometry and the processing conditions must all be modeled properly.

A skilled, experienced analyst will be able to evaluate those inputs to get the most out of the analysis. GIGO Rule AppliesĪny good simulation model depends on good inputs on several fronts. those in injection molding are orders of magnitude different. The viscosity levels for the shear rates in the MFI range vs. This graph shows curves for two different 20 MFI materials at the same range of temperatures. 1 MFI can be a poor predictor of how material will flow.

0 kommentar(er)

0 kommentar(er)